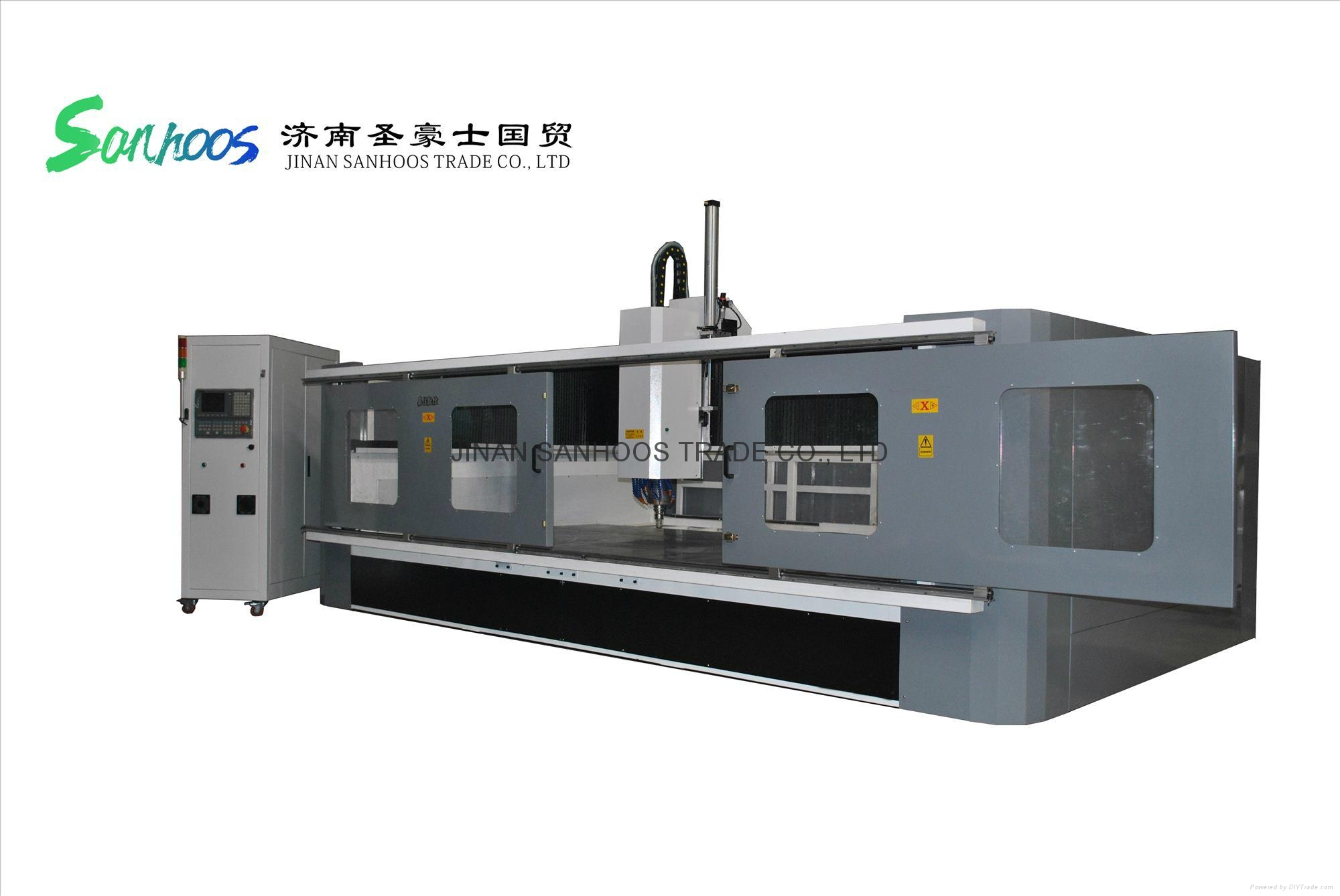

Sam Marble Granite Tools Chaing CNC Router Cutting Machine With ATC

Model No.︰SAM-ATC2030S

Brand Name︰Sam

Country of Origin︰China

Unit Price︰US $ 20000 / pc

Minimum Order︰1 pc

Product Description

Stone CNC Machining Center(SAM-ATC2030S)

|

Model |

SAM-ATC2030S |

|

|

X.Y.Z work area |

X axis |

3000mm |

|

Y axis |

2000mm |

|

|

Z axis |

350mm |

|

|

Model of CNC Automatic tool |

ISO-40 |

|

|

Spindle power |

16KW |

|

|

CNC Tool-store |

12r+12r(pieces) |

|

|

Vacuum pump |

50m³/h |

|

|

Max Processing Thickness |

200mm |

|

|

Automatic central lubricative device |

grease |

|

|

Electronic hand wheel button device |

EHDW-BA6S-IM |

|

|

Water Consumption |

40L/MIN |

|

|

compressed air pressure |

8 Bar |

|

|

Max Total Power Rate |

13KW |

|

|

Overall Size:L*W*H |

5.2X3.2X2.7M |

|

|

Weight |

4000KG |

|

Suitable Industry:

CNC machining center is a type of 3-dimensional CNC processing equipment designed and manufactured by us to meet nowadays processing pursuit of high precision, high speed, high efficiency under the drastic competition circumstances. The machine has the functions of milling, grinding, polishing and sculpting. It is especially suitable for producing high-grade basin board and other abnormal products made of stone, ceramic, glass and micro-crystal stone. The machine will automatically finish the processing of any required profile by simple setting. The products are of high precision and good glossiness rate. Furthermore, the machine can also run CNC programs to carry out different kinds of sculpting and mould processing etc.

Performance Characteristics:

1.Software: It can be applicable for many kinds of software, such as UncGraphics.NX3.0,Mastercam9.0 and so on ,integrating CAD/CAM, to program processing through digitized analysis and product design. It also can support files in many formats ,for example pre/igs/scep/dxf/dwp etc.

2.Auto tool-change system: The automatic system for changing tools is improving the integration all in terms of making holes, cutting, milling, shaping and polishing.

3.Cutting wheels and abrasives: Many kinds of cutting wheels and abrasives(both imported and China-made) are very easily available from local markets for various processing requirements

4.High precise ball screw and guide rail: The ball screw and guide rail are utilized by well-known Germany manufacturers. Unique oil-dip lubrication is applied for X and Y axis. The special water-proof and dirt-proof Structures can ensure better processing accuracy also prolong the life of screws and rails furthest.

Payment Terms︰ TT/LC